Smart Integration of AI and Digitalization in Tube Bending Machines

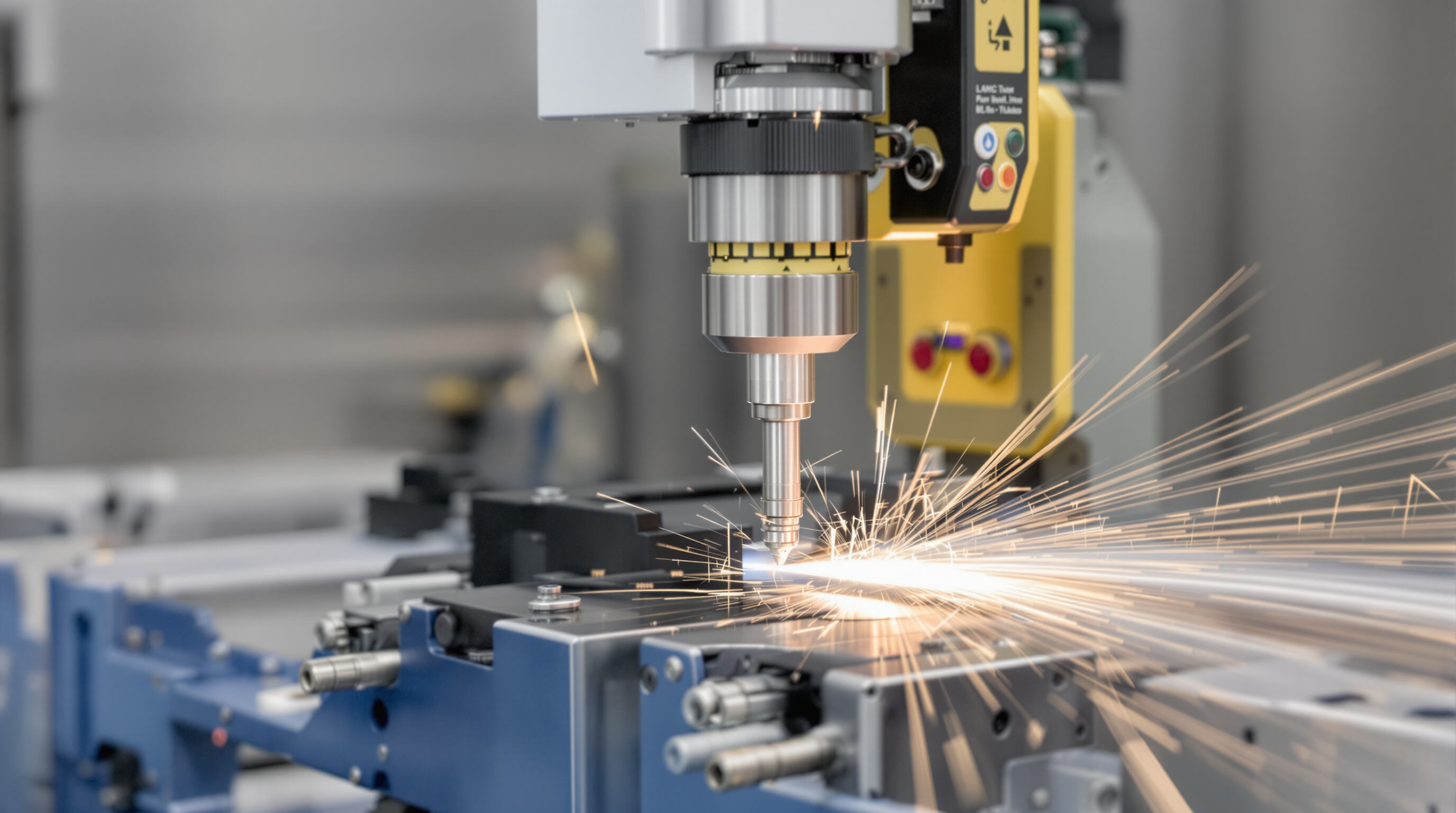

Modern tube bending machines are achieving unprecedented precision and flexibility through AI (Artificial Intelligence) and digitalization. These technologies optimize workflows while maintaining strict quality standards across industries like aerospace, automotive, and medical device manufacturing.

Artificial Intelligence and Machine Learning for Adaptive Bending Control

AI-powered systems analyze real-time sensor data to predict material springback, automatically adjusting tooling pressure and axis movements. Machine learning algorithms trained on historical bend sequences reduce setup times by up to 40% for new geometries. For example, automotive manufacturers using these systems report 99.3% first-pass accuracy in exhaust system bending (Ponemon 2023).

Digital Twin Technology and Advanced Software in CNC Pipe Bending

CNC (Computer Numerical Control) platforms now integrate digital twin simulations, enabling engineers to test bend sequences virtually before physical production. This eliminates material waste caused by trial-and-error adjustments. A leading aerospace supplier reduced prototype lead times by 28% using 3D bending simulations to validate fuel line geometries.

Balancing AI Automation with Human Oversight in Precision Tasks

While AI handles repetitive tasks like angle calculations and defect detection, skilled technicians remain critical for complex setups and geometric validations. Hybrid workflows pair machine learning with human expertise—operators review AI-generated bend plans and override parameters when handling high-value alloys or ultra-thin tubing.

CNC and Robotic Automation for High-Volume Tube Bending Production

Integrated CNC Systems for Consistent, High-Speed Output

Today's CNC tube benders can knock out jobs around 70% quicker than old school methods thanks to their combination of electric servos and instant feedback tech. The whole system works together to tweak things like how tight the clamp gets and what radius it bends to, keeping angles spot on within half a degree even when running nonstop day after day. Some high speed models handle those delicate stainless steel tubes at an incredible rate of 1200 bends per hour while still holding up structurally. No wonder these machines have become must haves in shops making parts for heating systems and refrigeration equipment where precision matters most.

Robotic Automation in Automotive Exhaust System Manufacturing

The combination of six axis robotic arms and vision guided tube bending equipment has really changed how exhaust systems get made these days, hitting around 98 percent accuracy right off the bat for those tricky mandrel bends. According to research from an automotive tier one supplier back in 2023, companies saw their scrap rates drop by forty percent after switching to robots for handling catalytic converter tubes. What makes these systems so valuable is their ability to adjust automatically for springback issues in strong alloys without losing track of tight tolerances. They keep things within 0.05 mm across entire 2.5 meter exhaust assemblies, which matters a lot when dealing with precision parts that need to fit together perfectly.

3D and High-Speed Bending Technologies for Complex Industrial Applications

Modern tube bending machines address increasingly complex manufacturing requirements through two transformative approaches: spatially adaptive 3D bending systems and ultra-rapid production technologies. These innovations meet strict tolerance demands across aerospace, automotive, and energy sectors while accelerating time-to-market for critical components.

Advancing 3D Pipe Bending for Aerospace and Intricate Geometries

Modern 3D tube benders work with 7-axis CNC sync to make those complex curves needed for plane fuel lines and reactor cooling systems. According to research from the Aerospace Manufacturing Consortium back in 2023, these advanced systems hit under 0.15mm accuracy when bending titanium alloys across multiple planes, which beats traditional techniques by around two thirds. The machines come equipped with built-in laser scanners that keep checking each bend angle against the digital plans, making real time adjustments as needed to account for springback issues especially common with tough stuff like Inconel 718. This kind of precision makes all the difference in critical applications where tolerances simply cannot be compromised.

Performance and Precision of High-Speed Tube Bending Machines

The latest high throughput models pair 400 RPM servo electric drives with smart machine learning algorithms, churning out around 1,200 automotive brake lines every single hour while keeping diameters consistent within plus or minus 0.1 mm according to Industrial Automation Quarterly from 2024. What's really impressive about this speed? It actually maintains incredible precision too. Real time strain sensors constantly tweak the mandrel pressure throughout those fast 3 second bending cycles, which stops the dreaded ovalization effect even when working with thin walled 0.8 mm stainless steel tubing. These kinds of performance specs are becoming absolutely essential for manufacturers making EV battery cooling pipes where they need massive production volumes but can't afford any microscopic defects that might cause failures down the line.

Hybrid Bending Techniques and Micro-Precision for Critical Industries

Merging Traditional and Modern Methods in Hybrid Tube Bending

Hybrid tube benders mix old school mechanical techniques with modern automation to tackle tough fabrication jobs. These machines integrate traditional rotary draw methods alongside computer controlled adjustments, hitting angular tolerances below plus or minus 0.1 degrees even when working with tricky materials like stainless steel or shape memory alloys. Power plants and shipyards have been adopting this hybrid approach for years now, especially when making parts that need both strength (think steam turbine tubes) and complicated shapes (like those manifold systems that distribute fluids throughout equipment). What makes these systems stand out is how they balance hands-on setup options with machine precision. Fabrication shops report cutting down on wasted material by around 18 percent compared to older purely mechanical setups, based on recent efficiency reports from the manufacturing sector in 2024.

Tolerance Control in Medical Device Tubing and Sensitive Applications

When it comes to medical grade tube bending, we're talking about work that requires almost microscopic precision. Most manufacturers now aim for dimensional accuracy around plus or minus 0.005 inches when making things like catheters and parts for surgical instruments. The latest machinery uses laser guided measurement tech that can check dimensions over 240 times each minute. These systems are smart enough to adjust automatically for what happens when materials like nitinol or titanium springs back after being bent. Getting this kind of micro precision right is essential for meeting FDA standards when producing implants. Surface finish matters too - anything rougher than 0.4 microns Ra can become a breeding ground for bacteria. Medical specific bending equipment differs from regular industrial models because they need to work in cleanrooms. These specialized systems are designed to prevent any particles from getting into sensitive medical products during manufacturing.

Material-Specific Innovations for Thin-Walled and High-Performance Alloy Bending

Preventing Deformation in Thin-Walled Tube Bending Processes

The latest generation of tube bending equipment features smart pressure control technology specifically designed to handle challenges with thin-walled materials. These advanced systems constantly tweak mandrel pressure settings and feeding speeds as the machine works, which cuts down on tube collapses during bends. Some studies from Chinese aviation research back this up showing around a third fewer failures when working with aluminum tubes used in aircraft parts compared to older fixed-pressure methods. When dealing with really thin walls under 1.2 millimeters thick, many shops turn to special composite sleeves that keep everything intact without compromising flexibility. These supports let technicians make tight radius bends as small as twice the actual tube size while still maintaining strength requirements.

Algorithms Tailored to Strength and Flexibility Demands of Advanced Alloys

The latest control software can handle those tricky springback issues found in nickel based superalloys and various titanium grades without breaking a sweat. These smart systems work with data coming straight from strain gauges and laser measuring devices as they go along, making adjustments to bending steps so that angles stay within half a degree even when temps swing between minus forty degrees Celsius and three hundred degrees. What does this mean practically? Well, manufacturers can now make those tiny medical stents used inside blood vessels or parts for nuclear plant cooling systems where getting the materials right isn't just important it's absolutely essential for safety reasons.

| Key Innovation | Material Application | Tolerance Benchmark | |

|---|---|---|---|

| Deformation Control | Active mandrel pressure regulation | Aluminum 7075-T6 | 0.8% ovality @ 3xD bend |

| Alloy-Specific Bending | Machine learning springback prediction | Inconel 718 | ±0.12mm positional repeatability |

FAQ Section

How does AI improve tube bending machines?

AI enhances tube bending machines by analyzing real-time sensor data to predict material springback, automatically adjusting tooling pressure, and reducing setup times by using historical data.

What is a digital twin in CNC pipe bending?

A digital twin in CNC pipe bending involves creating a virtual simulation of the bending process, which enables precise testing and adjustments before physical production, reducing material waste.

How do hybrid workflows benefit tube bending?

Hybrid workflows combine AI automation with human expertise, allowing machines to handle repetitive tasks while technicians oversee complex setups and manage high-value materials.

Table of Contents

- Smart Integration of AI and Digitalization in Tube Bending Machines

- CNC and Robotic Automation for High-Volume Tube Bending Production

- 3D and High-Speed Bending Technologies for Complex Industrial Applications

- Hybrid Bending Techniques and Micro-Precision for Critical Industries

- Material-Specific Innovations for Thin-Walled and High-Performance Alloy Bending

- FAQ Section