The Evolution and Impact of Chain Making Machine Technology

Historical Development and Key Technological Breakthroughs

Back in the 1920s, chain making was all about manual forging, but things started changing when semi automatic systems came along around mid century. Then came the big leap forward in the 1980s with CNC technology entering the scene. These computer controlled machines could bend wires with incredible accuracy down to about plus or minus 0.1 mm. And guess what? They slashed human errors by roughly 85% in important areas such as making conveyor chains according to some research published in the Journal of Manufacturing Technology back in 2020. Fast forward to the 2000s and we saw another shift where cold forming took over from traditional heating methods. This change helped cut down on energy consumption by about a third without compromising those ISO 9001 quality standards that manufacturers need to meet.

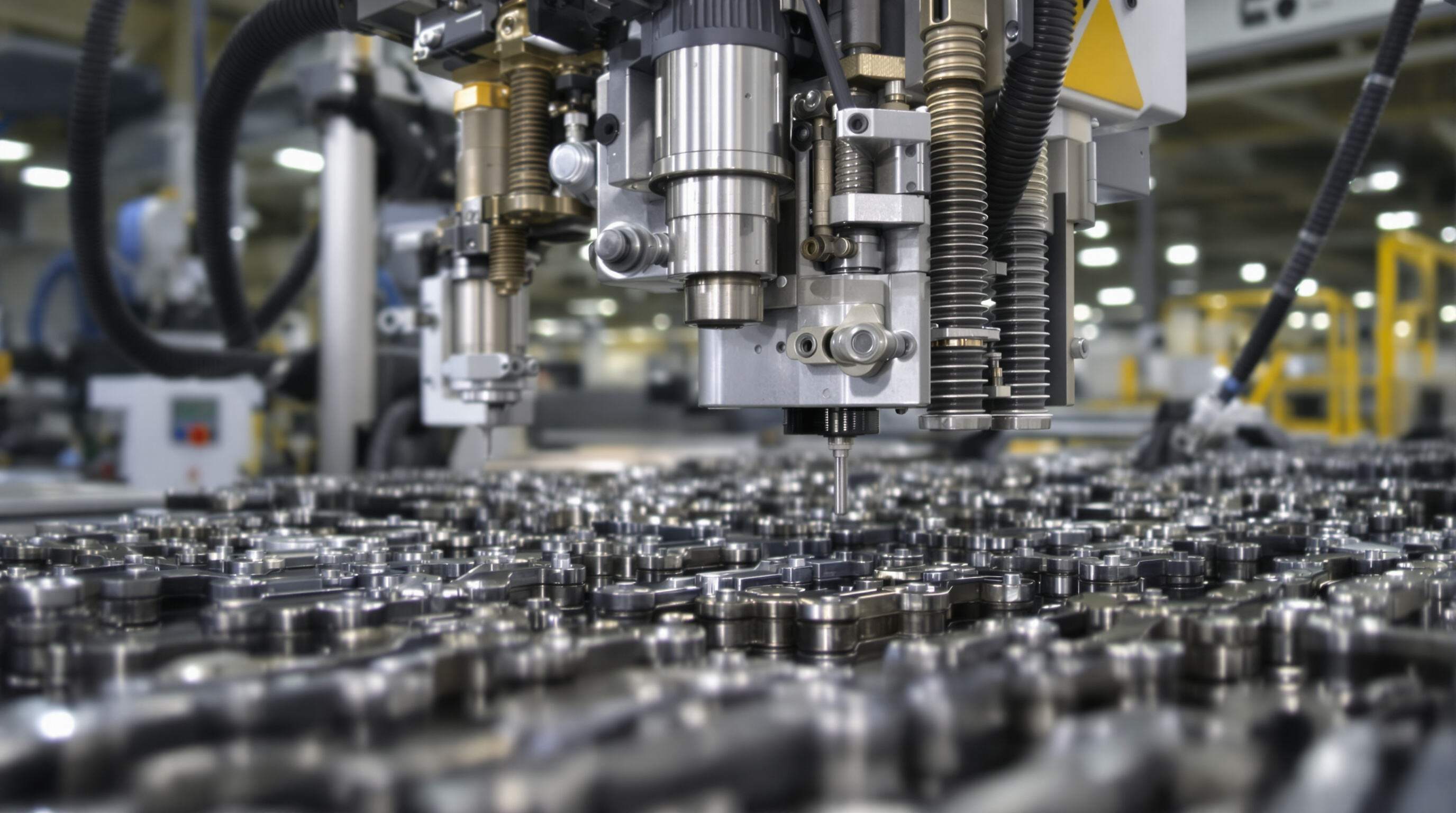

The Role of Automation in Modern Chain Making Machines

Today's chain making machines integrate robotic arms and IoT sensors to support 24/7 operations with defect rates below 0.3%. According to a 2022 PwC study, automation reduces labor costs by 40% and triples output capacity. Key features include:

- Self-adjusting tooling for producing roller, leaf, and conveyor chains

- Vision systems that detect micro-fractures during forming

- Predictive maintenance algorithms that prevent 92% of unplanned downtime

Data Insight: 60% Increase in Production Efficiency Since 2010

Technological advancements have significantly boosted productivity in chain manufacturing:

| Metric | Pre-2010 Baseline | 2023 Data | Improvement |

|---|---|---|---|

| Chains/hour | 800 | 1,280 | +60% |

| Energy Use/Unit | 5.2 kWh | 3.1 kWh | -40% |

| Defect Rate | 2.1% | 0.4% | -81% |

These gains are largely attributed to automated tool-changing systems and AI-driven quality control, as confirmed by IMA's 2023 industry analysis.

Precision and Performance: Chain Making Machines for Roller Chains

Engineering Accuracy in High-Speed Roller Chain Production

Modern chain manufacturing equipment now incorporates servo driven positioning along with closed loop feedback systems, enabling these machines to produce parts with incredible accuracy down to the micrometer level while running at impressive speeds over 1,200 links per minute. The result is better adherence to ANSI B29.1 specifications and significantly fewer issues with part tolerances. Older model machines typically show about 78% more variation in measurements. This improvement also means components last longer before wearing out, something that matters a lot for automotive timing chains specifically. A recent industry benchmark report from 2023 confirms these findings across multiple manufacturers.

Case Study: Chain Making Machine Integration in Automotive Supply Chains

A European Tier-1 automotive supplier reduced drivetrain assembly failures by 40% after adopting adaptive chain making machines equipped with in-line optical measurement. The system's real-time diameter adjustment accommodated six different alloy grades without tooling changes, streamlining production shifts between standard and corrosion-resistant roller chains for electric vehicles.

Material Compatibility and Durability Standards

Roller chain production now supports advanced materials, each requiring specialized machine capabilities:

| Material Type | Hardness (HRC) | Fatigue Limit (MPa) | Machine Requirement |

|---|---|---|---|

| Case-Hardened Steel | 58-62 | 850 | Plasma-coated forming dies |

| Nickel-Based Alloys | 45-50 | 1,100 | Temperature-controlled stations |

| Polymer-Composite | 85 (Shore D) | 500 | Low-inertia assembly arms |

To meet durability demands, stress testing requires 15,000-cycle endurance runs under 20% overload, with automated defect detection ensuring compliance.

Adapting Chain Making Machines for Conveyor and Leaf Chains

Modular Design for Conveyor Chain Applications in Food Processing

The modular chain making machines allow for quick changes to conveyor parts like cleats, guides, and different belt widths something that's really important for food processing plants dealing with all sorts of products on the same line. According to recent market research from 2024, around 7 out of 10 food manufacturers have started going modular because they want to cut down on those frustrating changeover times between production runs. These machines are typically built with stainless steel which makes sense given the hygiene requirements, plus they work well with Clean-In-Place systems. This combination helps meet both USDA and FDA standards for cleanliness in food manufacturing environments where contamination risks must be kept absolutely minimal at all times.

Specialized Tooling and Strength Testing for Leaf Chain Fabrication

Making leaf chains demands really precise tools to create those interlocking plates with gaps smaller than a tenth of a millimeter. Modern manufacturing setups now incorporate laser guides for alignment plus complex stress tests across several stages to satisfy the ISO 4347 standards for tension resistance. After production, quality checks reveal that almost all chains (about 98.6%) last beyond 50,000 cycles. That's actually a pretty impressive jump from just over 41,000 cycles back in 2018. The reason? Better materials used in the pins and bushings help them withstand much more wear and tear, especially important when these chains are put to work in heavy lifting scenarios such as inside forklift masts where constant strain is the norm.

Balancing Load Capacity and Flexibility: Industry Challenges

When creating chains for those tough industrial applications like heavy duty conveyors or articulated systems, engineers face some real design challenges balancing strength against flexibility. Thicker steel plates certainly handle massive weights, supporting loads as high as 15 tons in mining operations, but these same thick links often cause problems when trying to get proper engagement around 180 degree sprockets in cramped installation areas. Looking at actual field reports, about one third of early chain failures seem to stem from designs that sacrifice too much flexibility for raw strength. This has led many manufacturers to experiment with new materials combinations and different link arrangements, incorporating hybrid alloys along with staggered link patterns in their latest machine designs.

Future Innovations in Chain Making Machine Design and Sustainability

Smart Sensors and IoT Integration for Real-Time Monitoring

Chain manufacturing equipment these days comes packed with built-in smart sensors connected through the internet of things, keeping tabs on things like tension levels, proper alignment, and signs of wear as they happen. Take temperature monitoring for instance. When fabricating roller chains at high speeds, temperature sensors kick in to tweak cooling processes automatically. According to industry reports from last year, this helps cut down material stress somewhere between 12% and 18%. What really makes a difference though is when all these data points get collected across different production lines. Manufacturers can then predict quality issues before they occur, which means tighter control over specifications throughout entire manufacturing systems. The bottom line? Better products with fewer defects and wasted materials.

Energy-Efficient and Sustainable Chain Making Machine Models

Sustainability innovations include regenerative braking in servo motors, which cuts power consumption by 23%, and closed-loop coolant systems that recycle 95% of fluids. One leading European manufacturer has adopted solar-powered machines for leaf chain production, reducing annual carbon emissions by 1.2 metric tons per unit.

Predictive Maintenance Algorithms to Maximize Uptime

AI-powered algorithms analyze vibration and torque data to predict component failures with 89% accuracy. By scheduling repairs during planned downtime, these systems prevent costly stoppages–saving an average of $5,600 per hour (McKinsey 2022). Some platforms even autonomously order replacement parts, shortening supply chain lead times by 30–45 days.

FAQ

What are the main benefits of modern chain making machines?

Modern chain making machines offer significant benefits such as reduced labor costs by 40%, tripled output capacity, and minimized defect rates below 0.3% due to automation and integration of robotic and IoT technologies.

How has cold forming changed the chain manufacturing industry?

Cold forming replaced traditional heating methods, leading to a reduction in energy consumption by about a third while maintaining ISO 9001 quality standards, thus enhancing efficiency and reducing environmental impact.

In what ways do smart sensors and IoT improve chain making processes?

Smart sensors and IoT enable real-time monitoring of chain manufacturing equipment, helping to adjust processes automatically, predict quality issues beforehand, and ensure adherence to high standards across different production lines.