Understanding the Paint Roller Handle Making Machine Workflow

Key Components of a Paint Roller Handle Making Machine

Modern systems integrate material feeders, forming rollers, and stamping dies to transform metal or plastic blanks into durable handles. Precision guide rollers maintain alignment, while hydraulic punching units create ergonomic grip patterns. According to a 2023 industrial survey, using these components reduces material waste by 18% compared to manual methods.

How Automation Enhances Precision in Handle Fabrication

Automated sensors monitor bend angles within ±0.2° tolerance during wire forming, eliminating human measurement errors—a primary cause of deformation in manual production. Data from CNC-controlled systems show 92% consistency in handle curvature across 10,000-unit batches, ensuring uniform product quality.

Integration of CNC Technology in Machine Operation and Settings

CNC programming enables real-time adjustments to feed rates (3–15 m/min) and punch pressure (50–200 kN) based on material thickness. Operators can store over 50 handle profiles, allowing quick changeovers between straight-grip and ergonomic designs without compromising precision.

Maintenance Protocols for Continuous Production Efficiency

Daily calibration of forming rollers and weekly lubrication prevent 78% of unplanned downtime (Industrial Maintenance Journal 2023). Thermal sensors on motor drives trigger automatic shutdowns when temperatures exceed safe limits, safeguarding critical components and maintaining long-term operational reliability.

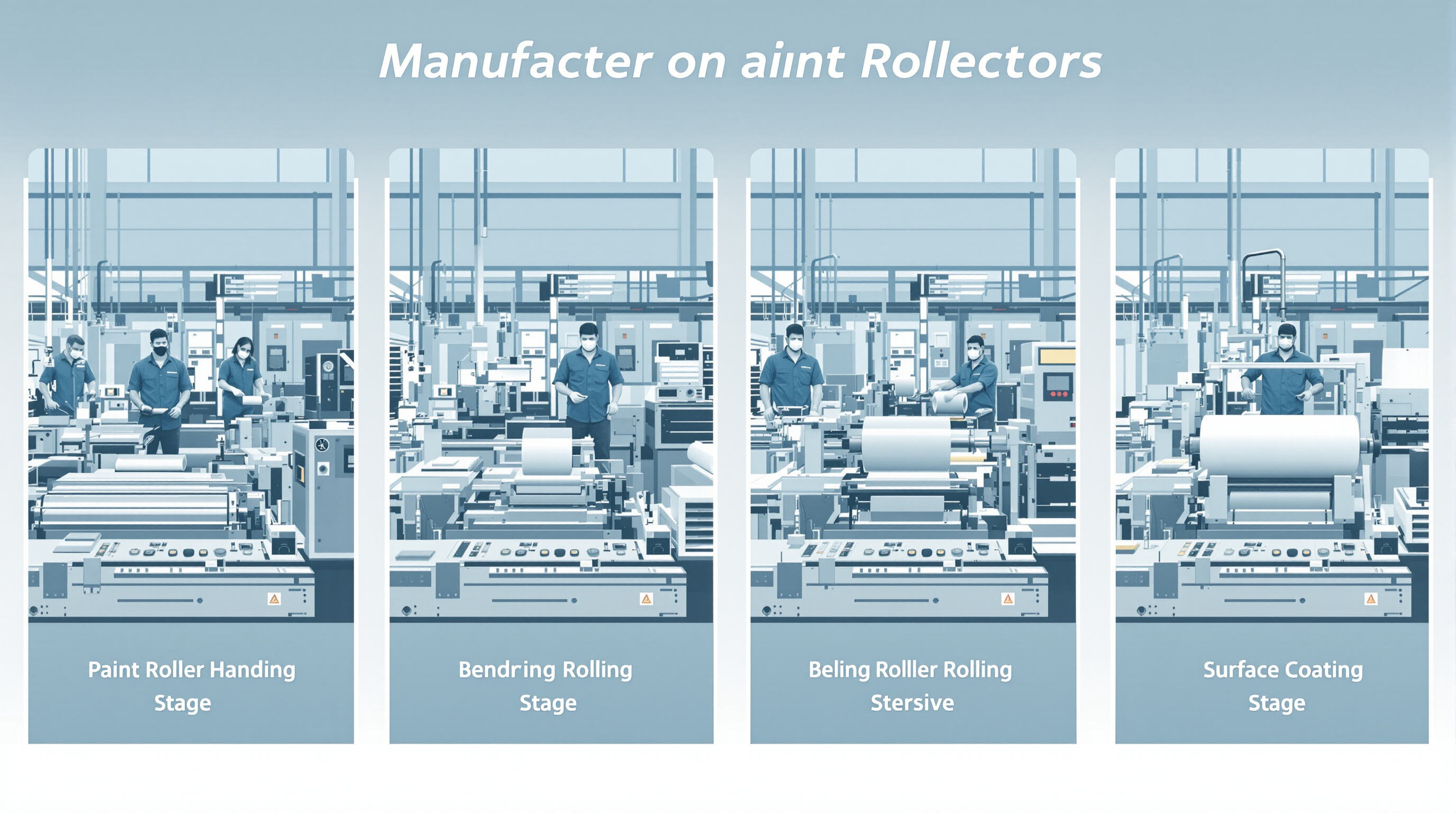

Core Stages of the Paint Roller Handle Manufacturing Process

Modern paint roller handle making machines execute four sequential stages to transform raw materials into precision-engineered tools. Each phase directly impacts durability, ergonomics, and production scalability.

Material Selection and Pre-Cutting for Handle Blanks

Aluminum (6061-T6) and stainless steel (Grade 304) are preferred for their 35–50% higher fatigue resistance than plastic composites (ASM International). Automated feeders direct metal coils into CNC laser cutters, producing blanks with ±0.1 mm accuracy and reducing material waste by 12–18% compared to manual cutting.

Bending Techniques Using Paint Roller Handle Bending Machine Operation and Settings

Servo-electric bending machines apply 850–1,200 N·m torque to form handles at 135° ±2°, the optimal angle for grip comfort. Cycle times range from 6 to 9 seconds per bend, with force sensors automatically compensating for springback in harder alloys to maintain dimensional accuracy.

Rolling and Shaping: Achieving Consistent Handle Profiles

Dual-axis forming rollers compress handles to diameters of 8–12 mm using a pressure gradient from 14 MPa (entry) to 22 MPa (exit). This progressive compression prevents fracturing while ensuring cross-sectional uniformity within 5% tolerance across production runs.

Surface Treatment and Coating for Enhanced Durability

Electrophoretic deposition (EPD) applies 25–40 μm epoxy coatings that withstand over 1,200 hours in salt-spray tests (ASTM B117), offering triple the corrosion resistance of conventional spray coatings. Infrared curing at 180°C completes polymerization in 90 seconds, enabling immediate inline inspection via automated thickness gauges.

Innovations in End Cap Fabrication and Attachment Technology

Injection Molding with Paint Roller Handle End Cap Making Machine

The latest injection molding systems can hit around 0.02 mm accuracy when making end caps, thanks to those fancy six axis robots and their ability to monitor material thickness on the fly. According to some market research from 2024, nearly four out of five manufacturers have switched to equipment with built in cooling channels these days. This change has slashed production cycles by almost a quarter compared to older methods. What's interesting is how all these improvements are helping companies move toward eco friendly materials such as PBS and PLA for their products. Paint roller handle makers especially benefit since they need to meet stricter environmental regulations while still keeping costs under control.

Material Compatibility Between Metal Handles and Plastic End Caps

Thermal expansion mismatches—aluminum (23 μm/m°C) and glass-reinforced polypropylene (31 μm/m°C)—can lead to stress fractures. Industry leaders address this using dual-material 3D printing at the interface, improving torque resistance by 142% (ASTM D2063), particularly in high-performance composite handles.

Adhesive vs. Mechanical Attachment: Performance and Industry Preferences

Epoxy adhesives are used in 61% of premium assemblies, offering 18.6 MPa shear strength (ISO 4587). While some manufacturers adopt hybrid mechanical-chemical bonding, a 2024 survey reveals 43% of industrial users prefer snap-fit designs for easier maintenance, whereas 57% choose permanent bonds for high-vibration applications.

Crimping, Welding, and Snap-Fit Systems: Structural Integrity Comparison

Radial crimping provides 290 N axial load capacity in steel handles, outperforming ultrasonic welding (190 N), making it ideal for professional-grade tools. Finite element analysis confirms hexagonal snap-fit patterns increase pull-out resistance by 67% over circular designs, especially in carbon fiber-reinforced composites (40% fiber content).

Optimizing Production Efficiency and Embracing Future Trends

Streamlining Multi-Stage Production Lines for Higher Output

Integrated automation synchronizes feeding, bending, and finishing stages, improving cycle times by 18–22%. AI-powered process mapping tools help identify bottlenecks—facilities using them reduced idle time by 34% while achieving 99.2% uptime (Frost & Sullivan, 2023). Key efficiency drivers include:

- Multi-axis robotic arms for simultaneous cutting and shaping

- Centralized HMI controls enabling sub-20-second changeovers

- Infrared sensors that dynamically adjust speed based on material thickness

Trend Analysis: Shift Toward Lightweight Composite Handles

More and more manufacturers are turning to aluminum-carbon fiber blends along with various polymer composites these days. These materials cut down handle weight anywhere from about 40% up to around 55% when compared against traditional steel options according to recent research from Materials Innovation Lab in 2024. Contractors really want their tools to stay below 14 ounces because working overhead all day causes serious wrist strain otherwise. As workplaces start incorporating more automation technology, there's growing pressure on designers to find that sweet spot between making things light enough but still strong enough. Take industrial rollers for instance they need at least 300 pounds per square inch of strength while remaining manageable in weight for daily operations across construction sites nationwide.

Testing and Quality Assurance in Automated Handle Manufacturing

AOI systems check every handle at least twelve times during production. They look at things like bend angles within plus or minus 0.35 degrees and measure coating thickness between fifty to seventy micrometers. These machines can inspect over a thousand units each hour without slowing down. The system uses real time algorithms to match each product against thousands of approved designs from our database. According to industry quality reports from ASQ in 2023, this approach gives us around 98.7 percent success rate on first attempts. We also run accelerated corrosion tests and perform torsion testing for fifty thousand cycles to mimic what happens after ten years of normal usage. All this makes sure our products meet the strict requirements set out in ANSI standard G195 for long lasting performance.

FAQ

What are the key components of a paint roller handle making machine?

Key components include material feeders, forming rollers, stamping dies, precision guide rollers, and hydraulic punching units that collectively help in transforming blanks into durable handles.

How does CNC technology improve production?

CNC programming allows real-time adjustments to machine settings, ensuring precision and consistency, and enables quick changeovers between handle profiles without losing quality.

What are the materials used for handle blanks?

Aluminum (6061-T6) and stainless steel (Grade 304) are preferred due to their higher fatigue resistance compared to plastic composites.

How does automation impact the manufacturing process?

Automation improves precision, reduces material waste, synchronizes production stages, and enhances cycle times while maintaining consistent product quality.